Drilling Operations Chemicals

Quick Contact

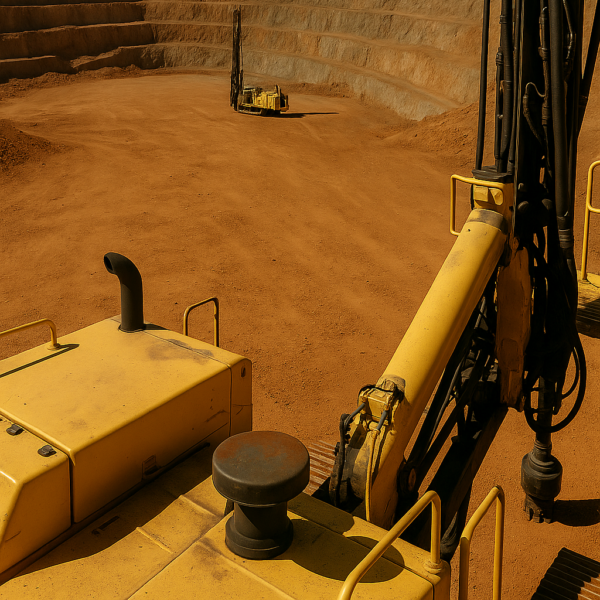

Built for Harsh Australian Drilling Environments

In the drilling industry, no day goes by without exposure to heavy soiling, extreme heat, abrasive residues and harsh working conditions. From the build-up of grease and oil on your machinery to the constant battle against dirt and drilling fluids on metal and plastic surfaces, your cleaning process must go beyond basic. That’s why purpose-designed cleaning chemicals for the drilling industry are essential.

At Liberato, we understand these exact conditions. That’s why we supply a complete range of industrial-grade cleaning chemicals tailored for drilling environments across Australia. These are products formulated not just to clean, but to protect, preserve and perform regardless of the terrain or task.

Protecting Equipment With Lubricants and Solvents

Your drilling equipment works hard and it gets dirty fast. Every moving part builds up residue, from hydraulic pistons to hammer heads. When grease thickens and oil leaks mix with dust and minerals, cleaning becomes a structural priority. Industrial solvents and effective cleaning agents made specifically for heavy industry are the only reliable way to tackle this kind of grime.

At Liberato, we supply lubricants, degreasers and cleaning solutions that perform under pressure. Rock drill lubricants and hammer greases reduce friction and wear, preventing rust and ensuring your machinery keeps running smoothly. These lubricants withstand high-pressure operations and don’t break down under heat. When matched with compatible degreasers, you’re not just cleaning you’re restoring and protecting equipment for the long haul.

Degreasers and Washes That Cut Through the Toughest Grime

There’s no escaping it—drilling work creates a lot of mess. The oil that powers your rig ends up coating every component. Grease migrates across surfaces. Dirt hardens around baseplates and clogs joints. To clean effectively, you need commercial-grade degreasers designed to break down the most stubborn soils.

Liberato’s degreasers mix specialised surfactants with industrial-strength agents, allowing them to emulsify grease, oil and grime rapidly. Whether you’re washing heavy machinery, engine bays or transport vehicles, the cleaning chemicals you use must strip contaminants without damaging equipment. These products rinse off easily and leave no film, even on sensitive surfaces like plastic and painted metal.

With the right tools, you can achieve faster turnaround, save labour hours, and reduce chemical waste. Pairing our solutions with foam cannons or pressure systems boosts productivity without compromising cleaning results.

Hygiene, Stain Control and Safer Site Conditions

Cleaning in the drilling industry goes beyond machinery. It extends to workspaces, vehicles and facilities especially those dealing with human touchpoints or food zones. That’s why Liberato’s range also includes disinfectants and antibacterial agents that destroy mould, bacteria, and viruses commonly found in industrial and healthcare environments.

Heavy-duty hand cleaners with natural grit remove industrial grime without irritating the skin. Surface disinfectants keep kitchens, bathrooms and crew hubs safe from microbial growth. Carpet and glass cleaners, formulated for industrial use, eliminate stain build-up while preserving surfaces and air quality.

And when safety matters most, our spill kits and absorbents act fast. Whether you’re dealing with hazardous oil leaks or chemical mishandling, Liberato supplies the equipment you need to act quickly, stay compliant and protect the environment.

Local Solutions Designed for Australian Industry

Unlike offshore imports, Liberato’s products are developed with Australian standards, working conditions and legislation in mind. That means they’re effective in extreme heat, suitable for local terrain, and fully compliant with regulatory frameworks. Our full product range is backed by clear and accessible safety data sheets, so you’re always prepared for audits or on-site training.

When you order with Liberato, you’re sourcing locally made cleaning chemicals designed specifically for the drilling industry chemicals that arrive faster, perform better, and support Australian business.

Supporting the Entire Drilling Supply Chain

Whether you’re running on-site operations, maintaining depot equipment, or supplying materials to subcontractors, your cleaning demands vary—but your expectations don’t. You need solutions that handle rust, grime, grease and fuel oil, while also supporting hygiene in high-traffic and shared spaces.

That’s why Liberato’s product range is designed for versatility. From degreasers used on rig components to surface cleaners for control rooms and disinfectants for portable toilets, our cleaning products serve every corner of your operation. They work across metals, plastics, glass and rubber, ensuring safety and efficiency without compromise.

Why Drilling Professionals Choose Liberato

Choosing the right supplier is as important as choosing the right product. At Liberato, we’re not just a distributor we’re your maintenance partner. We provide expert advice on product selection, bulk ordering solutions, and responsive support that adapts to your schedule.

Every chemical is backed by technical documentation, proven use cases and reliable availability. Our clients rely on us for high-performance cleaning chemicals that boost equipment efficiency, improve safety, and streamline compliance.

You can clean with confidence, knowing your operation is supported by an Australian supplier with deep industry experience and unwavering commitment to quality.

Get the Right Chemicals, Ready When You Are

You already know what poor cleaning practices can cost equipment breakdowns, compliance failures and production delays. So why take chances? Choose industrial-grade cleaning chemicals from Liberato and take control of your site’s cleanliness, safety and performance.

Whether you’re restocking degreasers, updating your chemical storage, or looking for advice on cleaning protocols, we’ve got you covered. Contact us today to discover which products best suit your drilling environment and let’s keep your operation running at full capacity. Because at Liberato, clean isn’t just a standard it’s a strategy.

Frequently Asked Questions

The best cleaning chemicals for drilling include industrial degreasers, heavy-duty lubricants, hammer greases, and solvents designed to remove oil, grease and residue from equipment. Liberato supplies products formulated specifically for harsh Australian drilling environments.

Yes. Every product supplied by Liberato includes a full safety data sheet (SDS) outlining proper handling, usage, and hazard information. These documents are essential for compliance, training and onsite safety.

Absolutely. Our range includes degreasers and solvents that are highly effective against heavy soiling, embedded grease, and corrosion on metal surfaces. They’re formulated to break down contaminants quickly and rinse cleanly.

Yes. Liberato offers cleaning products suitable for a range of materials, including plastic, glass, rubber and painted metal. Each product is tested for compatibility and performance on delicate surfaces.

We offer disinfectants and antibacterial surface cleaners suitable for food prep zones, crew kitchens, and healthcare stations on drilling sites. These products are effective against bacteria, mould, and viruses, supporting safe and hygienic environments.

Yes. Liberato offers national delivery with fast turnaround. Our logistics team ensures timely supply for remote and metro drilling sites across Australia, with bulk options available.